Lab grown diamonds can be growing through two processes: high pressure, high temperature (HPHT) and chemical vapor deposition (CVD method). General Electric made fake diamonds in the 1950s using a method called High Pressure High Temperature (HPHT). Small, dense diamonds were meant for industry, not jewelry.

The commercial industry has benefited considerably from the usage of HPHT synthetic diamonds in cutting, surgical, and electrical instruments. For their satellites, NASA ordered HPHT diamonds because of their density, hardness, thermal conductivity, and heat-resistance characteristics.

The CVD technique for producing synthetic diamonds is the latest and most refined method. These diamonds boast exceptional quality, color, and clarity, surpassing those created through HPHT methods.

CVD makes diamonds with less pressure and smaller equipment than HPHT, by copying how diamonds form in space gas clouds.

CVD diamonds are created to be stunning diamonds that are perfect for diamond engagement rings and high-end jewelry. These lab-grown diamonds are evaluated using the same standards as natural diamonds. In contrast to lab-grown diamonds, cubic zirconia and other diamond simulants lack the genuineness and resilience of genuine diamonds.

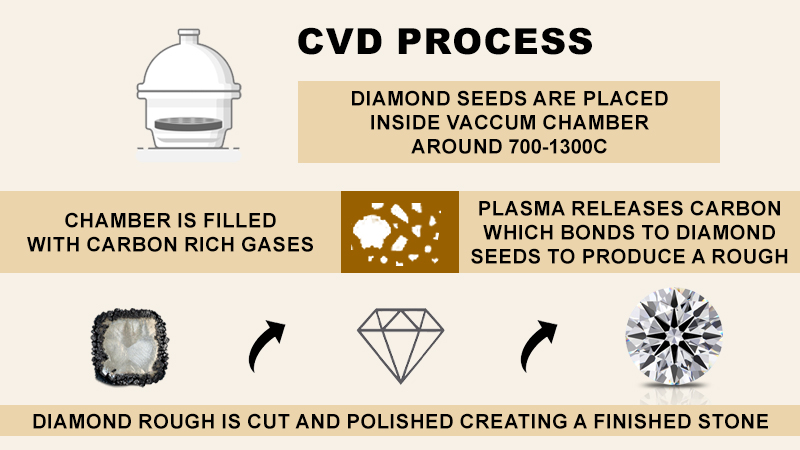

What is a CVD diamond?

The Chemical Vapor Deposition method is used to create CVD diamonds. A tiny lab used gas, heat, and pressure to make a big, pure diamond in a sealed chamber. The following steps are involved in the manufacture of CVD diamonds:

Vacuum Chamber

We firmly place small diamond kernels, typically a slender diamond layer or graphite piece, within a vacuum enclosure.

Carbon Gas Exposure

Diamonds form in interstellar gas clouds in space, like methane and hydrogen. These clouds create diamonds that have lots of carbon.

Raise the Temperature

The chamber's temperature is adjusted to 900-1200°C.

Produce Energy

The laser beam disintegrates the carbon and charges the plasma, and then it layers onto the diamond seed. The energy for the laser beam is created by heating and ionizing plasma.

Remove Flaws

Scientists take diamonds out of a chamber every few days to make them better by cleaning them and removing extra carbon.

Cutting and Polishing

Once the diamond seeds have crystallized, they are cut cleanly and fully polished after three to four weeks.

In most cases, the CVD process takes three to four weeks to turn small diamond crystals into the finished product. Diamonds are created by breaking down carbon gas and allowing carbon atoms to adhere to pre-existing diamond nuclei. The time required to create a diamond varies. It is dependent on the size of the room, the diamond's characteristics, and the number of diamond seeds.

Crystals produced through CVD are typically brownish with a slight touch of black graphite prior to being polished. Heat is used to remove the brown color and the black graphite is cut.

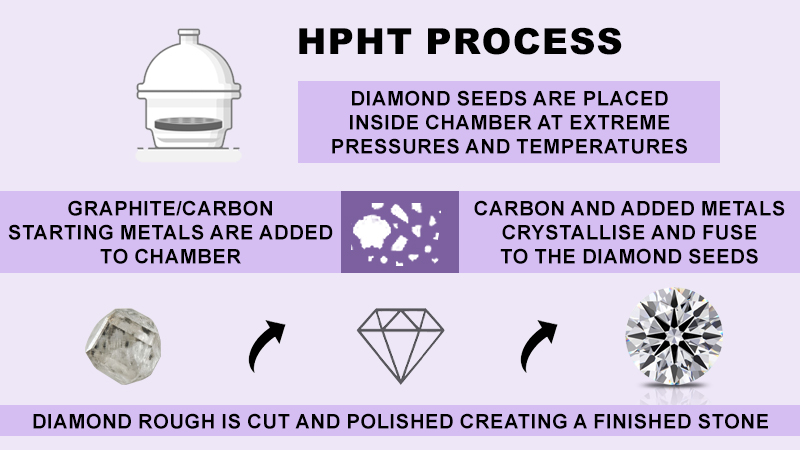

What is an HPHT Diamond?

Lab-grown diamonds produced through the High Pressure; High Temperature technique are known as HPHT diamonds. There are two methods to create diamonds: CVD and HPHT. CVD uses gas on a small diamond, while HPHT process uses high heat and pressure like what happens in nature. The HPHT lab-grown diamonds growth process comprises of the subsequent stages.

Customized Press

Scientists deposit a diamond seed layer by layer into a press chamber created specifically for HPHT-lab created diamonds.

Control the Temperature and Pressure

They create diamonds like those found in mines by heating and pressurizing a chamber. The required conditions are a temperature range of 1300-1600°C and a pressure of 870,000 pounds per square inch.

Carbon Dissolution

Melted metal speeds up the dissolution of pure carbon sources, and carbon atoms ionise in layers around the diamond seed.

Cutting and Polishing

Carbon ionization produces a synthetic diamond, which is cut and polished.

A tiny filament in the HPHT diamond chamber increases the temperature of the chamber. Lab diamonds can be made with less heat and pressure by using metal filaments like iron or cobalt. The carbon atoms become diamonds on the cool parts of the seed, making a fake diamond seed. It takes a while to make crystals, depending on the seeds, equipment, and conditions.

How Gemologists Identify HPHT and CVD Diamond?

Color Distribution

HPHT created diamonds have an uneven color distribution. A geometric pattern is formed by the concentration of components such as nitrogen within the HPHT stone. Because nitrogen distributes to select areas of the diamond rather than covering the entire diamond, the color distribution is uneven.

The color distribution of CVD lab grown diamonds is uniform. When making lab-grown diamonds, things like hydrogen and methane mix in and spread out evenly. This makes the diamond look the same all over and have a regular shape.

Patterns of Graining

Lab diamonds have grain, but the pattern is different in CVD and HPHT diamonds. A special diamond has a cross shape and unique pattern. This makes it possible to measure its shape and growth with fancy tools. Because CVD diamonds lack a geometric shape, crisscross structure, or specific internal growth composition, diamonds lack graining pattern.

Fluorescence Color Patterns

Real diamonds glow brighter under long-wave UV lights. Fake diamonds, however, glow brighter under short-wave UV lights. HPHT-created diamonds have a cross-shaped fluorescence color pattern on their crown or pavilion after cutting. CVD diamonds do not usually exhibit a fluorescence color pattern, but when they do, the pattern is striped.

Phosphorescence on Rare Occasions

Both CVD and HPHT diamonds exhibit phosphorescence on occasion. Lab-made diamonds can glow in unusual colors, such as orange. This occurs when they are kept in certain areas after the UV light is switched off. CVD diamonds glow blue when exposed to UV radiation during their creation, and their price can vary.

Inclusions

diamond formed in laboratories feature black or opaque metal flux inclusions but a metallic brilliance beneath transmitted light. CVD diamonds have inclusions as well, but unlike HPHT diamonds, their inclusions are mineral or dark graphite. They do not have a magnetic pull since they do not contain flux metal inclusions.

Patterns of Strain

HTHP diamonds are made like natural diamonds, but with controlled pressure and temperature to avoid stress. HPHT diamonds don't show strain patterns and are worth more than CVD diamonds because they don't experience stress. Conversely, CVD diamonds undergo changes in temperature and pressure, leading to distinct strain patterns.

Girdle Inscription

To tell lab diamonds apart from natural ones, look for a tiny mark on the edge of the lab diamond. You need a special tool to see it clearly. The girdle of a diamond is its most expansive section, which dictates the visibility and size of the inscription. If laboratories do not engrave synthetic diamonds, organizations that authenticate diamonds engrave the girdle.

Inscriptions are possible on both CVD and HPHT diamonds. A small laser mark on a CVD diamond shows it's not from a mine like other diamonds.

Conclusion

The truth is that gemologists cannot agree on which lab grown diamond is better hpht or cvd. Colourless diamonds can be created using both CVD and HPHT techniques. Experts and groups like GIA and IGI categorize lab-made diamonds by their color, patterns, marks, and flaws.

Lab-made diamonds, CVD and HPHT, are chemically and physically same like Earth-mined diamonds in composition. But they have some differences. Because not every lab-grown diamond will have the same graining patterns, inclusions, and phosphorescence. GIA invented indicators to help jewelers and consumers identify the jewels.