Lab grown diamond are real diamond just like naturally mined diamond and are chemically physically and optically identical to natural diamond. Lab grown diamonds are also known as cultured diamonds and man-made diamonds.

Lab grown diamonds are created using cutting-edge technology. This technology duplicates the conditions found in the Earth's mantle, beneath the crust. This is the environment where diamonds naturally form.

Typically, lab grown diamonds are 40-50% less expensive than natural diamond. Two techniques are used to produce lab-made diamonds: HPHT and CVD. HPHT stands for High-Pressure High Temperature. CVD stands for Chemical Vapor Deposition.

Today, we will discuss HPHT. It is the most common method used to create diamonds. This process involves subjecting a diamond seed to extreme pressure and heat in a laboratory.

This process mimics the natural process of diamond formation and takes anywhere from a few days to a few weeks. The CVD method breaks down methane gas into its component parts. Then, it deposits carbon atoms onto a diamond seed. This process takes around a week and the resulting diamond is usually of higher clarity than those created using HPHT.

The HPHT method is the most cost-effective way of creating lab-grown diamonds. CVD method, on the other hand, produces diamonds with higher clarity. Ultimately, both methods are an environmentally friendly way to create diamonds in a laboratory, and both have their own unique benefits. Lab grow diamonds are becoming increasingly popular, and for many people, they are the preferred choice for purchasing diamonds.

Lab grown diamonds are a great alternative to mined diamonds. They are more affordable and better for the environment. They are also becoming increasingly popular for diamond engagement rings and other jewelry pieces. Lets discuss in depth how lab grown diamonds are made.

Are Lab Grown Diamonds Real?

Lab created diamonds made through two main processes: HPHT (High Pressure High Temperature) and CVD (Chemical Vapor Deposition). HPHT (High Pressure High Temperature) is a process used to create diamonds. It starts with a small piece of a mined diamond, which is referred to as the diamond seed. This seed is then subjected to the same high temperatures and pressures as those found in the Earth's mantle.

This process results in the growth of a diamond crystal. CVD is a process.

A diamond seed is placed in a chamber. The chamber is then bombarded with plasma.

The plasma is created from a mixture of gases. This process causes the diamond to form in the chamber.

Both of these processes can produce diamonds with similar characteristics to mined diamonds, including color, clarity, and cut. The HPHT method is the most cost-effective way of creating a lab grown diamond. In contrast, the CVD method produces diamonds with higher clarity. Ultimately, both methods are an environmentally friendly way to create diamonds in a laboratory, and both have their own unique benefits.

Diamond simulants are real diamonds, composed of the same chemical makeup as mined diamonds. The only difference is that lab grown diamonds are created in a laboratory, rather than mined from the Earth. Synthetic diamonds are certified and graded in the same way as mined diamonds. This process is overseen by organizations such as the Gemological Institute of America (GIA).

Lab grown diamonds are becoming increasingly popular, and for many people, they are the preferred choice for purchasing diamonds. Lab grown diamonds are a great choice for those who want to save money or be more eco-friendly. They provide an alternative to mined diamonds. They are also becoming increasingly popular for engagement rings and other jewelry pieces.

Lab grown diamonds are real diamonds. They are identical to natural diamonds in every way.

Both types of diamonds share the same quality and characteristics, such as: Chemical Composition: C Crystalline Structure: Cubic Refractive Index: 2.42 Dispersion: 0.044 Hardness (MOHS): 10 Density: 3.52 People are increasingly choosing lab-grown diamonds over mined diamonds. Lab-grown diamonds are more affordable and sustainable. Additionally, they provide complete assurance that the diamonds were ethically sourced. And will test as diamond using any diamond testing method.

Lab grown diamonds are created in a lab environment by replicating the natural process of diamond formation. Scientists use advanced technology. They replicate the high pressure and temperature conditions that exist deep within the Earth. These are the same conditions where diamonds are formed naturally.

A diamond seed is placed in a growth chamber. It is then subjected to high temperatures and pressures. This encourages the diamond to grow.

The process of obtaining a diamond may take some time. It could be a few weeks, or even a few months. This depends on the size and quality of the diamond desired.

There are two main processes used to form lab grown diamonds, High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

HPHT Stands for High Pressure High Temperature

The HPHT process involves placing the diamond seed in a growth chamber and exposing it to extreme temperatures and pressures. The temperature and pressure is slowly increased, causing the diamond seed to grow over time. This process is typically used to grow larger, more expensive diamonds.

The CVD process uses plasma to create a vaporous form of carbon, which is then deposited onto the diamond seed. The diamond seed is then exposed to heat and pressure, causing the carbon to form a diamond. This process is typically used to grow smaller, less expensive diamonds.

HPHT diamond production process was first invented in the 1950s to create brilliant and beautiful diamonds.

Step 1. To grow an HPHT diamond, a process begins with a small diamond seed which is placed inside a press. Together with a piece of carbon, such as graphite and metal catalyst, such as nickel or iron.

Step 2. The diamond seed is exposed to a high temperature of 1300 - 1600°C. It is then pressurized using one of three methods: a belt press, a cubic press, or a split sphere press. This pressurization reaches approximately 1.5 million pounds per square inch.

Step 3. Pure carbon begins to melt with pressure and heat. Carbon atoms slowly accumulate around the crystal over several days to weeks. This results in the formation of a multi-sided crystal structure.

Step 4. The diamond is left to cool before it is ready for cutting, polishing, and setting. This is the same process used to shape a diamond found in nature.

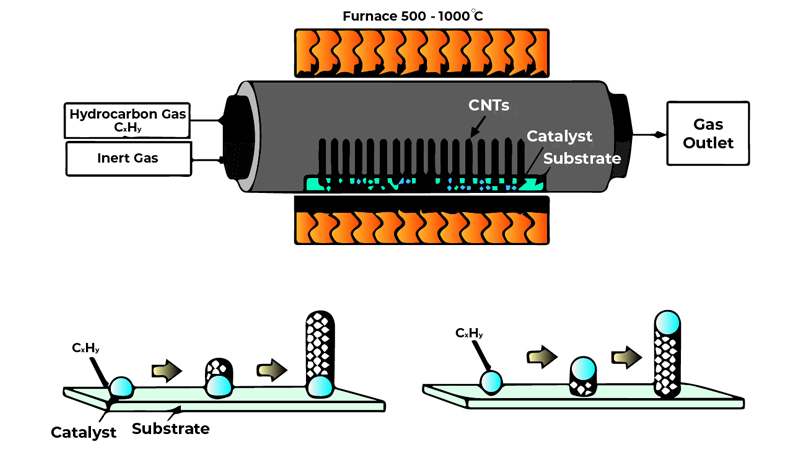

CVD Stands for Chemical Vapor Deposition

Step 5. The diamond is put into a vacuum chamber. A gas mixture of hydrogen and methane is heated there to a very high temperature. The heated gas mixture breaks down into its component atoms, which deposit onto the diamond seed.

This process is repeated until a diamond layer has formed on the diamond seed.

Step 6. The diamond is removed from the chamber. It is then cut and polished to its final form. This process is the same as cutting and polishing a naturally formed diamond.

CVD diamonds are created in a controlled environment using plasma technology. The CVD Process was invented in the 1980s making it newer than the HPHT method. Some names of the first creators of CVD diamonds are: W.G. Eversole, Derjaguin and J. C. Angus.

Step 1. To grow a CVD diamond, a process begins with a small diamond seed. This seed is placed inside a sealed chamber. The chamber is heated to over 1,400 Fahrenheit. Then, a stream of carbon-containing gas, such as methane, is introduced.

Step 2. These gases are then ionized and created plasma using technology similar to microwaves, lasers, and other devices.

Step 3. This process breaks down the molecular bond of the gas. As a result, carbon pieces are released towards the colder, flat diamond seed plates. Additional treatments may be used to enhance or change the diamond’s color after it is grown.

Step 4. Crystallization happens over the course of a few weeks, with multiple crystals developing simultaneously. This is contingent on the size of the space as well as the number of seed plates used. Once the diamond reaches its desired size it is then removed from the machine and set into its final form.

Conclusion

The process of creating lab-grown diamonds is a complex and delicate one. It requires using the right technology and materials, and a great deal of time and patience.

The outcome is a beautiful diamond. It is identical to a mined diamond in every aspect. However, benefits of lab grown is, it does not have the negative environmental and ethical aspects of diamond mining.

The lab grown diamond mimics the same conditions we can find within the naturally mined diamonds. Unlike natural diamonds, which take billions of years to form, lab-grown diamonds can be created in a matter of weeks.

Understand the difference between HPHT and CVD diamonds. It is now time to decide which one is the right choice for you. Considering CVD for bigger diamond. But if you are looking for a high-quality diamond then the HPHT is the better option.

Ultimately the decision to get an HPHT or CVD diamond comes to your personal preferences. Lab grown diamonds, like mined diamonds, come with a grading report. This report gives you peace of mind that you are getting the quality diamond you expect.