- USA & CA : 1(800) 618-0057

- UK : 0800-158-8052

- Australia : 1800-195-871

Need help?

If you'd like to speak to an expert about selecting the right diamond for you, please call:

1-800-618-0057

[email protected]

Javda Jewelry would be pleased to assist you in finding or making the special ring you've been looking for. Just e-mail us at [email protected] with your request and we can send you a quote or will contact you for additional information. We are specialized in creating custom engagement rings.

Many of the mountings on our site can be customized as per your choice of metals and diamonds. In addition, we also have hundreds of other mountings available to suit your needs. You can e-mail us if there are any kind of changes to be made with the diamond, gemstones or the metals. If you are unable to find something that suites your taste on our website, all you have to do is e-mail us about the same and we will be happy to help you find what you are looking for. Be it a design of your own imagination or something similar to a piece you may have seen elsewhere. Our designers will create exactly what is in your mind.

How It Works

Whether you want to create an engagement ring, wedding band, 3 stones ring or solitaire ring, all you have to do is speak to our expert designer and they will create a sketch as per your requirement.

Call us on 1(800)-618-0057 or e-mail us at [email protected]. Javda Jewelry is ready to discuss your design ideas and requirements.

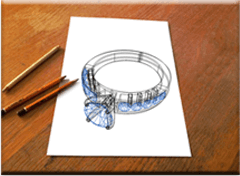

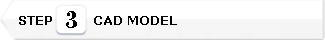

Once we have a full understanding of the piece you would like to create. The sketch is sent to our expert CAD designers, who then create a basic wire frame model in their software. It gives rough idea about how the design will look.

A CAD model of the design is created by the designer as pear your requirements. You will get to see your design in an exact way as it will be casted. You can also have a look at the setting of the diamond as well.

Once you are happy with your design, it will then send for wax piece by our expert design team. This should take around 0-00 weeks, depending on the complexity of your design.

When you cast an object such as a ring, you form it using a mold. Wax is used and the object to be made is crafted in wax. The wax is coated with plaster and then the wax is removed through heating the mold, leaving a hollow form. Melted gold is then poured in this hollow mold and the ring is casted. The mold is then allowed to rest till the metal solifies.

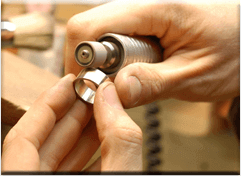

The ring is handed to the polisher. Using a rubberized mounted silicon wheel, spinning and containing an abrasive compound, the polisher creates a smoothed metal finish. It cuts and smoothes the metal’s surface and removes visible traces of sanding, filing, or other abrasive procedures. A large polishing brush is then applied to pre-polish the outside of the ring. A smaller "dental" brush cleans hard-to-reach inside areas and crevices. Additional tools like a cross-sander may also be applied.

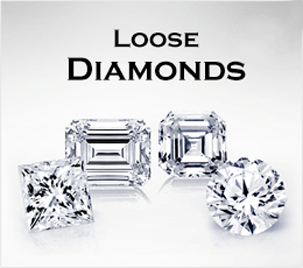

Mostly loose diamonds are professionally set into engagement rings or other fine jewelry using specialized tools, lighting, drills, and heat. When used in jewelry, diamonds can take on a strong sentimental value, often passed down as an heirloom from one generation to the next.

The polishing process and diamond setting process is concluded and a final ultrasonic cleaning, steam-cleaning and electro-cleaning are conducted.The ring, whether platinum or gold will now possess a striking mirror-like luster. Before the ring is sent to the shipping department, it is given to the quality controller who follows a ten point checklist to confirm, among other things, proper diamond or gemstone seating and pronging (if appropriate), pristine metal finishing, and appropriate hallmarking.The finished ring is now handed to the packing and shipping department and delivered the product to the customer.

US & CA :

US & CA :

Live Chat

Live Chat

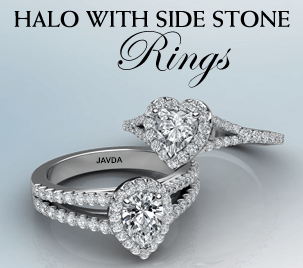

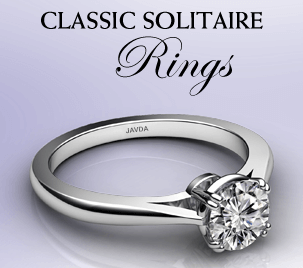

Engagement Rings

Engagement Rings

Pendents

Pendents

Natural Diamond's

Natural Diamond's

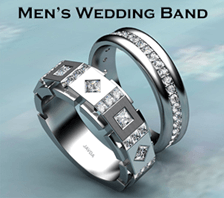

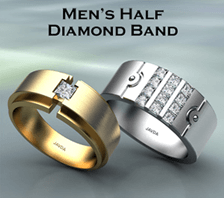

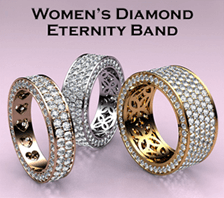

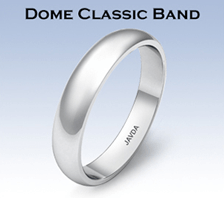

Wedding Bands

Wedding Bands

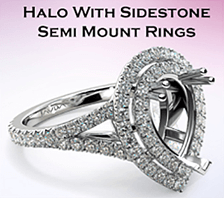

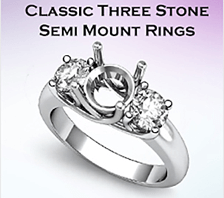

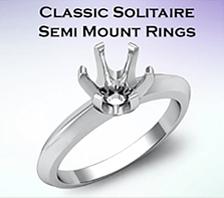

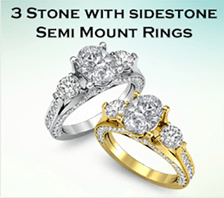

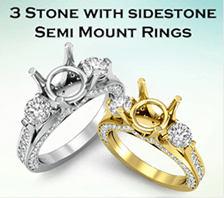

Semi mount rings

Semi mount rings